1. Liwiro la screw

M'mbuyomu, njira yayikulu yowonjezerera kutulutsa kwa extruder inali kukulitsa kukula kwa screw. Ngakhale kuwonjezeka kwa wononga m'mimba mwake kumawonjezera kuchuluka kwa zinthu zomwe zimatulutsidwa pa nthawi ya unit. Koma extruder si conveyor wononga. Kuphatikiza pa kutulutsa zinthuzo, wonongayo imatulutsanso, imasakaniza ndikumeta pulasitiki kuti ipange pulasitiki. Pansi pa liwiro la wononga nthawi zonse, kusanganikirana ndi kumeta ubweya wa wononga ndi mainchesi akulu ndi phula lalikulu pazakuthupi sikwabwino ngati wononga ndi mainchesi ang'onoang'ono. Choncho, extruders masiku makamaka kuonjezera mphamvu poonjezera liwiro wononga. Liwiro wononga wa extruder wamba ndi 60 kuti 90 rpm kwa extruders chikhalidwe. Ndipo tsopano zawonjezeka kufika 100 mpaka 120 rpm. Ma extruder othamanga kwambiri amafika 150 mpaka 180 rpm.

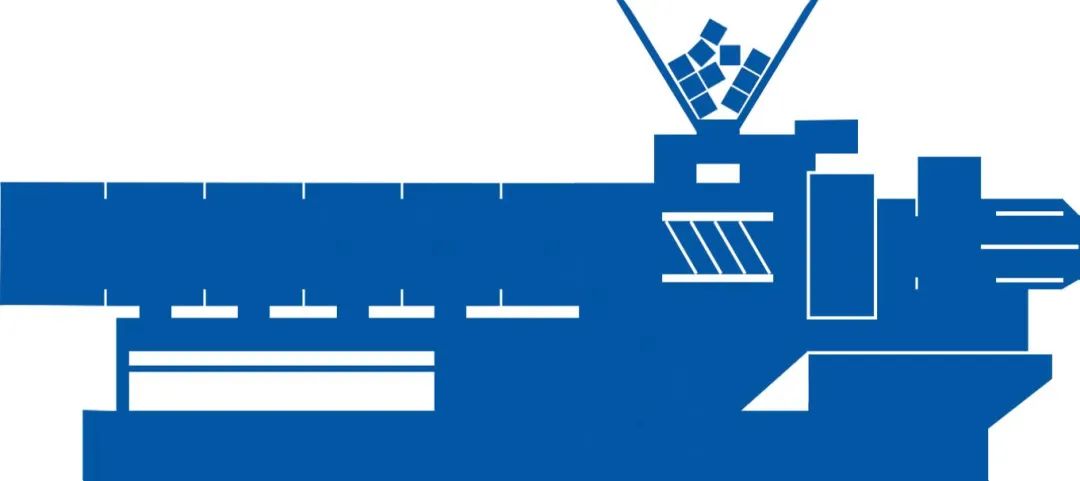

2. Zomangamanga

The wononga kapangidwe ndi chinthu chachikulu chimene chimakhudza mphamvu extruder. Popanda dongosolo wononga wololera, kuyesera kungowonjezera wononga wononga liwiro kuonjezera extrusion mphamvu ndi zotsutsana ndi cholinga lamulo ndipo sizingakhale bwino. Mapangidwe a wononga othamanga kwambiri komanso othamanga kwambiri amatengera kuthamanga kwambiri kozungulira. Mphamvu ya pulasitiki ya mtundu uwu wa screw idzakhala yosauka pa liwiro lotsika, koma zotsatira za plasticizing zidzasintha pang'onopang'ono pamene liwiro la screw likuwonjezeka, ndipo zotsatira zabwino zidzapezedwa pamene liwiro la mapangidwe likufika. Panthawiyi, mphamvu zonse zapamwamba komanso zotsatira zoyenerera za plasticizing zimatheka.

3. Gearbox

Mtengo wopangira chochepetsera umakhala wolingana ndi kukula kwake ndi kulemera kwake, malinga ngati mawonekedwewo ali ofanana. Kukula kwakukulu ndi kulemera kwa bokosi la gear kumatanthauza kuti zida zambiri zimagwiritsidwa ntchito popanga ndipo zotengera zomwe zimagwiritsidwa ntchito ndizokulirapo, zomwe zimawonjezera mtengo wopanga. Pankhani ya kutulutsa kwa ma unit, mphamvu yotsika yamagalimoto ndi kulemera kochepa kwa bokosi la giya wothamanga kwambiri wothamanga kwambiri kumatanthauza kuti mtengo wopangira pagawo lililonse lotulutsa chiwongolero chokwera kwambiri ndi chotsika kuposa cha extruder wamba.

4. Kuyendetsa galimoto

Pakuti yemweyo wononga m'mimba mwake extruder, liwilo ndi mkulu dzuwa extruder amadya mphamvu kuposa extruder ochiritsira, choncho m'pofunika kuonjezera galimoto mphamvu. Pa ntchito yachibadwa ya extruder, galimoto galimoto dongosolo ndi Kutentha ndi kuzirala dongosolo ntchito nthawi zonse. Yemweyo wononga m'mimba mwake extruder ndi galimoto zikuluzikulu zikuoneka kuti mphamvu njala, koma ngati masamu ndi linanena bungwe, liwilo ndi mkulu dzuwa extruder ndi mphamvu yothandiza kuposa extruder ochiritsira.

5. Kugwedera damping miyeso

Ma extruder othamanga kwambiri amatha kugwedezeka, ndipo kugwedezeka kwakukulu kumawononga kwambiri kugwiritsa ntchito bwino zida ndi moyo wautumiki wa magawowo. Chifukwa chake, njira zingapo ziyenera kuchitidwa kuti muchepetse kugwedezeka kwa extruder kuti muwonjezere moyo wautumiki wa zida.

6. Zida

Kupanga kwa extrusion kwenikweni ndi bokosi lakuda, ndipo momwe zinthu zilili mkati mwake sizingawonekere konse, ndipo zitha kuwonetsedwa kudzera pazida. Choncho, zida zolondola, zanzeru komanso zosavuta kugwiritsa ntchito zidzatipangitsa kumvetsetsa bwino momwe zilili mkati mwake, kotero kuti kupanga kungathe kupeza zotsatira zofulumira komanso zabwino.

Nthawi yotumiza: Mar-01-2023